|

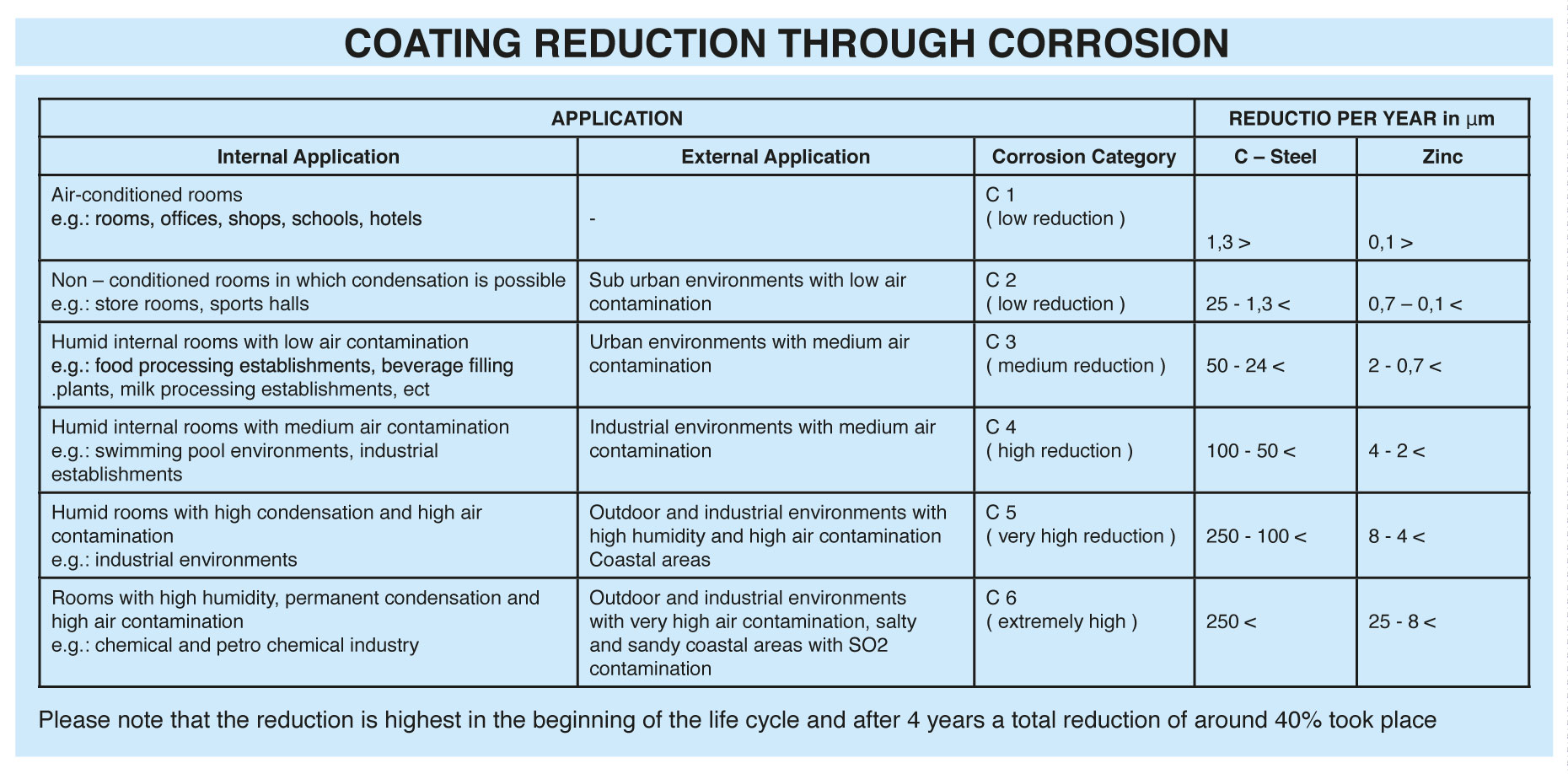

| Hot dip galvanized steel delivers maintenance�free corrosion protection for 75 years or more, in even the most corrosive atmospheres. The zinc coating is actually harder than the steel it is protecting, and will retain a consistent matte gray finish throughout its service life. |

| Because galvanizing requires no maintenance, the initial cost of a bridge, mass transit station, sign structure, etc. is the �nal cost. Therefore, hot dip galvanized steel is the lowest life cycle cost corrosion protection system available, far more economical than painted steel or concrete, which require frequent and costly maintenance according to a predictable cycle. |

| The energy input over the life (60 year study) of hot dip galvanized steel is less than half of painted steel. There is no energy, material, or labor input for maintenance throughout the project lifetime (including no unnecessary transportation of material and labor to the project site for each maintenance cycle). |

| Hot dip galvanizing makes steel structures (handrail, guard rail, bridges, signs) safer. The galvanizing process applies zinc on difficult to reach corners and the inside of poles, box girders, towers, and handrail; places where corrosion usually begins on painted and unprotected steel. |

| Zinc and steel are 100% recyclable, without the loss of chemical or physical properties. Galvanized steel has been used to protect automobile and truck body panels for decades, because it protects the consumer's investment and there is no end of life environmental impact. |