BOX MANUFACTURING

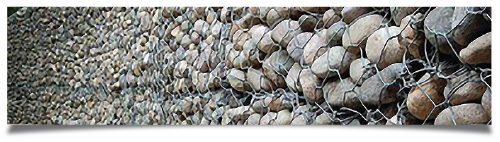

Dunes Industries is into manufacturing and supply of mechanically woven double twisted gabion boxes having their manufacturing facility at Sohar Free Zone. Gabions are rectangular wire mesh baskets filled with rock at the project site to form flexible, permeable, monolithic structures such as retaining walls for commercial, industrial and road projects. Gabions are used as modular construction blocks to prevent soil erosion. They offer an alternative solution to concrete structures. Gabions, by virtue of their matchless strength, excellent engineering adaptability and proven reliability, have become the chosen building material for the tremendous variety of construction works.

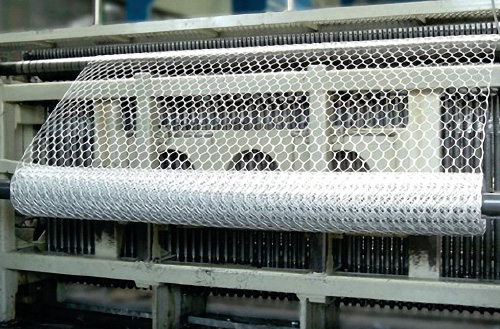

One of the key factors in the long term performance of gabions is the quality of the wire used for the mesh,

selvedge wire and lacing wire. Dunes gabions are manufactured from high quality steel wire woven into a double twist hexagonal mesh to give both mechanical strength and prevent unravelling. The quality of the wire is strictly controlled and conforms to BS 1052:1980 for tensile strength.

Gabions are typically a permanent or semi-permanent slope and/or soil stabilization application.

Typical installations include:

Retaining walls

Bridge abutments and wing walls

Culvert headwalls and outlet aprons

Shore and beach protection

Water recharge dams / Check dams

Rock slide protection works

River training works

Stone filling is characterized by porosity that enables water to flow and doesn’t create hydraulic pressure on the panels of gabion structures, it has drainage function.

Gabions are able to deform while still retaining their integrity, they adapt themselves to terrain where the concrete structures may crack and fail, they are suitable for unstable subgrades.

The high resistance and durability is secured by outstanding features of steel wire, its surface treatment by heavy galvanization or PVC coating and by the quality of stone filling. During the lifetime the pores are filled up with alluvia and the whole structure is grown through by vegetation what increases its strength and therefore is able to resist against great pressures.

Gabion baskets are made from double twisted, hexagonal woven wire mesh. The wire used to manufacture the gabion baskets is fabricated from high quality tensile, heavily galvanized steel, which is also available with an extruded PVC coating for additional corrosion protection, when required by the application. The double twist of the woven wire mesh provides integrity, strength and continuity to the structure by adding a non-raveling effect that prevents any accidental damage from spreading.

Gabion installations are more economical than rigid or semi-rigid structures for a number of reasons. The first reason being that little maintenance is required. Graded stone fill is usually locally available. The gabion construction is simple and hence does not require skilled labour. Also minimum foundation preparation is required for the installation, the surface needs to be only reasonably plane.

Gabion structures during their lifetime merge with surrounding nature, they are grown over by local vegetation, look more aesthetic than concrete structures. In the rivers they enable algae to anchor and to accommodate micro-organisms for natural water cleaning. They are nice complement to landscape.

Gabions, by virtue of their matchless strength, excellent engineering adaptability and proven reliability, have become the chosen building material for the tremendous variety of construction works.

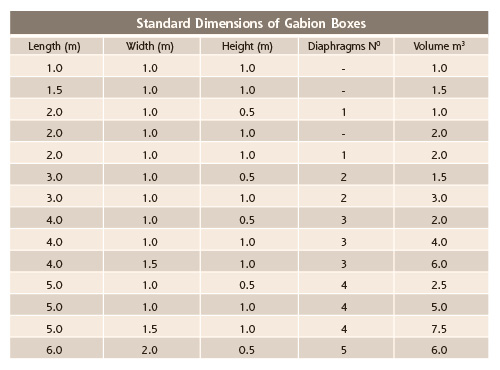

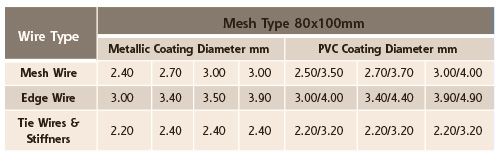

Gabions are baskets manufactured from 80x100mm double twisted hexagonal woven steel wire mesh. Gabions are filled with stones at the project site to form flexible, permeable, monolithic structures such as retaining walls, channel linings, and weirs for erosion control projects. The steel wire used in the manufacture of the gabion is heavily zinc coated soft temper steel.

Gabions depend mainly on the interlocking of the individual stones and rocks within the wire mesh for internal stability, and their mass or weight to resist hydraulic and earth forces. Gabions are a porous type of structure that can sometimes be vegetated.

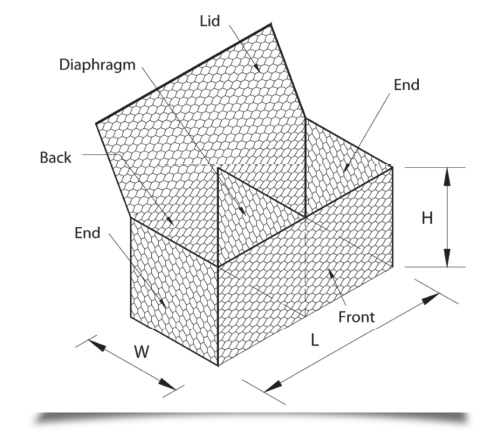

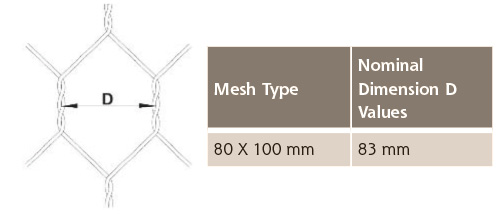

These are manufactured from mechanically woven double twisted hexagonal wire mesh using Heavily Galvanized steel wire. The edges of the mesh are reinforced with a thicker wire called the selvedge wire to strengthen them and to facilitate construction. Gabions can be divided into cells by fitting diaphragms which reinforce the structure and make installation easier.

In case of marine or highly corrosive environment, an additional protection is provided by extruding a 0.5mm to 0.8mm thick PVC coating over the heavily galvanized wire. PVC coating is done on the galvanized wire prior to manufacturing of the gabion mesh.

For easy handling and shipping, gabions are supplied folded into a flat position and bundled together.

Gabions are readily assembled by unfolding and binding together all vertical edges with lengths of connecting wire stitched around the vertical edges.

The empty gabions are placed in position and wired to adjoining gabions. They are then filled with stones to one-third their depth.

Connecting wires, placed in each direction, brace opposing gabion walls together. The wires prevent the gabion baskets from “bulging” as they are filled. This operation is repeated until the gabion is filled.

After filling, the top is folded shut and wired to the ends, sides, and diaphragms.

Corrosion Protection: Wire shall be zinc coated to BSEN10244-2; 2009.

Wire Diameter: BS 1052 and tolerances meet BS 443/82.

Wire Tensile Strength of 350N/mm² - 500N/mm²: EN10223-3, BS1052/80 and ASTM A64197.

Tolerances on diameter of galvanized wire: EN10218, ASTM A97597.

Elongation at break is min 10% and test to be carried out on a sample of minimum 25cm long before manufacturing (EN10223-3) or No less than 12% in accordance with ASTM A37092

Diameter of Mesh Wire: No less than 3.05 mm.

Coating of Wire: No less than 275gm/m².

Diameter of Selvedge Wire: No less than 3.50&3.90 mm.

Coating of Wire: No less than 275gm/m².

Diameter of Mesh Wire: No less than 2.69 mm, plus the PVC coating, total 3.708 mm.

Coating of Wire: No less than 275gm/m².

Diameter of Selvedge Wire: No less than 3.40mm, plus the PVC coating, total 4.39 mm.

Coating of Wire: No less than 275gm/m².

Retaining: Their use as earth retaining structures provides a low cost alternative to concrete or masonry retaining walls.

Drainage: The permeability of gabion structures has the benefit of reducing pore water pressures behind the structure and allowing free drainage.

Erosion: The use of gabions allows erosion protection to be achieved using smaller stones and reduced thickness than would be required for conventional rip-rap. Gabions can also provide a cost effective, more aesthetically pleasing and environmentally friendly alternative to concrete systems.

Retaining Walls: Flexible gabion structures used in the construction of retaining walls are a simple, functional solution. These structures can withstand harsh environmental and climatic conditions.

Protection of Highways: Highways are infrastructures representing heavy investment. It is therefore vital to protect them from environmental disasters. Gabions are used to stabilize the slopes protecting the shoulders of highways that are prone to erosion. Highway protection work also includes rock-fall protection, retaining structures, culvert and bridge protection, where mesh fabric, gabion boxes or mattresses are used depending on the situation.

Rock-fall Protection: Protection against rock-fall from slopes can be guaranteed by using various structural solutions or by merely using gabion mesh fabric as a passive measure. The gabion mesh obstructs rock-fall and protects infrastructures. This is achieved by joining together rolls of mesh fabric with lacing wire and using it as a blanket to cover slopes. Alternatively, gabion retaining walls are built which stop falling rocks.

Protection of Culverts and Bridges: An unconfined flow of water causes erosion and may result in costly damage to main structures. In order to prevent this potential danger, gabion boxes and mattresses are used to guide the flow of water. These gabion boxes and mattresses are used extensively in the construction of culverts.

Channel Lining: The main function of the gabion structures is to control and guide the course of water through channels and prevent the erosion of banks. Due to the flexibility and permeability of these structures, they permit the natural movement of ground water.

Marine Works: Special Polypropylene coated wires, highly resistant to corrosion and other environmental effects are used in the manufacture of gabions for marine works. Beach protection, marinas, retaining walls, ramps, piers and small jetties can be built at great speed and minimum cost. Gabions allow wave energy to be dissipated thus conserving beaches and preventing erosion.